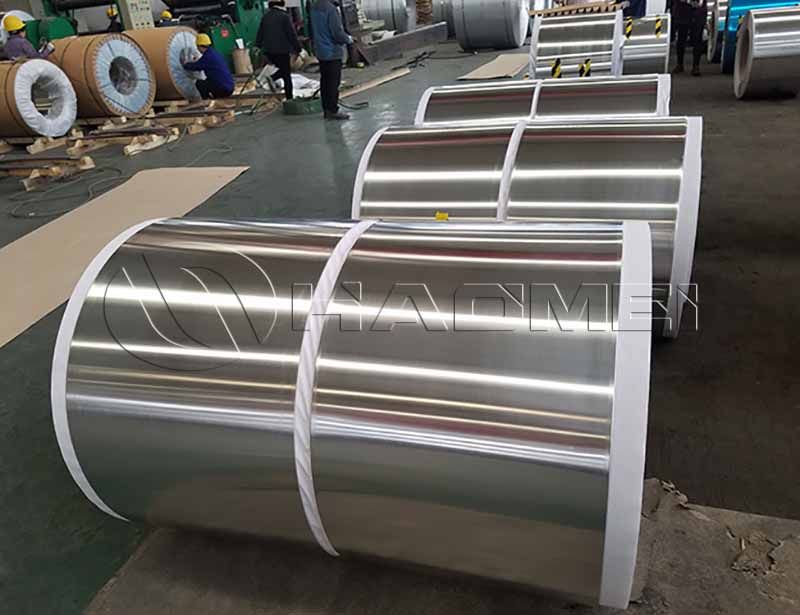

Aluminum Strip for Insulation

In many fields such as building energy conservation, industrial pipelines, and home appliance manufacturing, thermal insulation is an indispensable core component. It not only relates to energy loss control but also affects user experience and safety. Among numerous thermal insulation materials, aluminum strips for sale, with its unique material advantages, has become a "key player" hidden behind the insulation layer.

Why Aluminum Strip?

The core reason why the aluminum strip for insulation has become a core material lies in its properties precisely matching the needs. It possesses multiple superior properties, providing crucial guarantees for thermal insulation performance. Here are its most core advantages:

First, excellent barrier properties. The dense molecular structure of aluminum effectively blocks the penetration of air and moisture. This locks in a dry environment within the insulation layer, ensuring long-term stable insulation performance.

Second, good heat reflection performance. Aluminum has extremely high heat reflectivity, reflecting most radiant heat back, reducing heat absorption and conduction. In high-temperature environments, this reflective property effectively prevents heat transfer to the interior; in low-temperature environments, it reduces heat loss from the interior, improving insulation efficiency in both directions.

In addition, aluminum strip boasts advantages such as lightweight, ease of processing, and corrosion resistance. Its good ductility allows for cutting and bending to suit various complex pipe and equipment shapes. Surface-treated aluminum strip exhibits enhanced oxidation and corrosion resistance, adapting to diverse environmental conditions and extending the lifespan of insulation systems.

Core Application Scenarios

1. Construction industry

In the construction industry, aluminium strip is primarily used for exterior wall and roof insulation. In exterior wall insulation, it seals the joints of insulation boards, preventing air and rainwater infiltration and enhancing overall integrity. In roofing projects, it acts as an insulating layer, reflecting sunlight for cooling while blocking moisture to prevent leaks.

2. Industrial pipelines

Insulation of industrial pipelines relies heavily on the "sealing + reflection" function of aluminum strip coil. Wrapped around the outer layer of the insulation, it secures the material and blocks air convection. Its heat-reflective properties reduce heat transfer, and in high-temperature industries, it offers superior high-temperature and corrosion resistance.

3. Home appliance manufacturing

In home appliance manufacturing, aluminum strip is a core insulation component for refrigerators and air conditioners. Inside refrigerators, it adheres to the inner side of the foam layer to form a reflective insulation layer, reducing cold air penetration and lowering power consumption. In air conditioners, it's used to seal and insulate the outer layer of components such as the evaporator, ensuring effective cooling and heating.

4. New energy sector

In the new energy sector, aluminum strips are increasingly widely used for thermal insulation. In photovoltaic modules, it's used for backsheet insulation, reducing the impact of temperature on battery efficiency. In energy storage devices, it provides insulation and sealing, preventing abnormal temperature and humidity from affecting performance and ensuring stable equipment operation.

Usage reminders

Firstly, choose the appropriate specifications and models. Different scenarios require different thicknesses, widths, and surface treatments (such as coating or adhesive) for the aluminum strip. For example, thicker, high-temperature-resistant aluminum strips should be selected for industrial high-temperature pipelines, while thinner, adhesive-coated aluminum strips can be chosen for the interior of household appliances. The appropriate type should be selected based on specific needs.

Secondly, ensure construction quality. When wrapping and pasting the aluminum strip coil, ensure it adheres tightly to the insulation layer, without bubbles or wrinkles. Joints must be sealed tightly to avoid gaps that could reduce insulation effectiveness.

Thirdly, pay attention to environmental adaptability. In humid and highly corrosive environments (such as the seaside or chemical workshops), aluminum strips that have undergone anti-corrosion treatment (such as coated aluminum strips or anodized aluminum strips) should be selected to extend their service life.

Original source: https://www.aluminumstrip24.com/news/aluminum-strip-for-insulation.html

Tags: aluminum strips for sale,

Previous: 3003 Aluminum Strip for Cooking Utensils

Next: Aluminum Strip For Transformer