What Are Aluminum Strips’ Diverse Applications

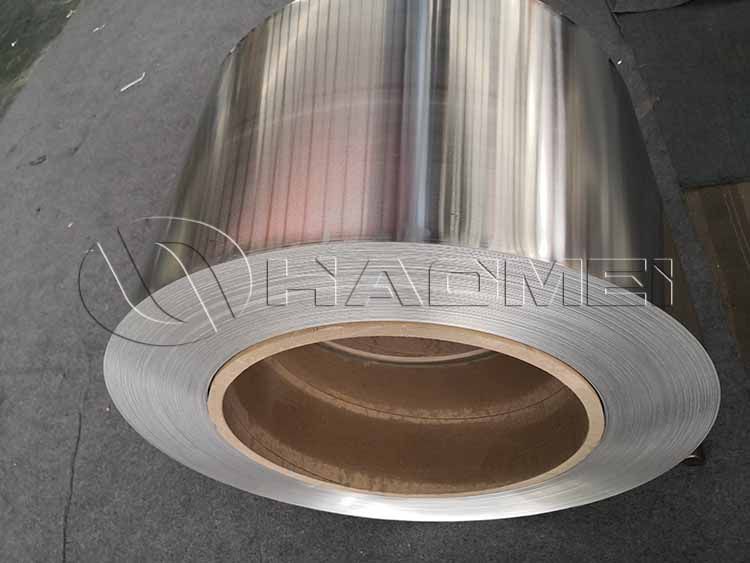

In modern industry and daily life, aluminum strips, as a multifunctional material, are playing an increasingly important role. With its unique physical and chemical properties, aluminum strips for sale are widely used in transformers, hollow glass, lamps, ceilings and other fields, providing strong support for the development of these industries.

Aluminum transformer strip

In the field of transformer manufacturing, aluminum strip is one of the indispensable core materials. As a key equipment in the power transmission and distribution system, the performance of the transformer directly affects the stability and efficiency of the power supply. Aluminum strip has become an ideal choice for making transformer winding due to its good conductivity and low cost. Compared with traditional copper winding, aluminum strip winding can not only effectively reduce the manufacturing cost of transformers, but also have a lighter weight, which is of great significance for some application scenarios with strict weight requirements, such as aerospace and mobile substations.

In addition, the corrosion resistance of aluminum strips also enables transformers to operate stably under harsh environmental conditions and prolong the service life of the equipment. In the manufacturing process of transformers, aluminum strips like 25mm x 1mm aluminium strip have good processing performance and can be made into windings of various shapes and specifications according to different design requirements to meet diverse market needs.

Window spacer

Aluminum strips are made into a frame structure of hollow aluminum strips through a special processing technology, providing stable support for hollow glass.

The lightweight characteristics of aluminum strips enable hollow aluminum strips to reduce the weight of the entire door, window or curtain wall system while ensuring strength, reducing the difficulty and cost of installation.

At the same time, the good thermal insulation performance of aluminum strips effectively prevents the transfer of heat, improves the energy efficiency of buildings, and meets the requirements of modern buildings for energy conservation and environmental protection.

In addition, the surface of aluminum strips can be treated in various ways, such as anodizing, spraying, etc., so that it has rich colors and beautiful appearance, meeting the design needs of different architectural styles.

Lamp manufacturing

In the lamp manufacturing industry, aluminum strips also play an important role. With the continuous improvement of people's requirements for lamp performance and appearance, aluminum strips have become the preferred material for lamp housings and radiators with their excellent heat dissipation performance, good processing performance and beautiful appearance.

The lamp will generate a lot of heat during operation. If it cannot be dissipated in time, it will affect the service life and luminous efficiency of the lamp. Aluminum strips have good thermal conductivity and can quickly conduct the heat generated by the lamp to ensure the stable operation of the lamp. 1/2 inch wide aluminum strip is often used.

At the same time, aluminum strips can be made into lamp housings of various shapes and styles through stamping, stretching and other processing processes to meet consumers' needs for personalized and beautiful lamps. In addition, the corrosion resistance of aluminum strips also enables lamps to be used normally in harsh environments such as humidity, acid and alkali, extending the service life of lamps.

Original source: https://www.aluminumstrip24.com/news/what-are-aluminum-strips-diverse-applications.html

Tags: aluminum strips for sale,

Previous: What Is The Aluminum Strip Used For

Next: 1000 Series Aluminum Strip and Their Uses?