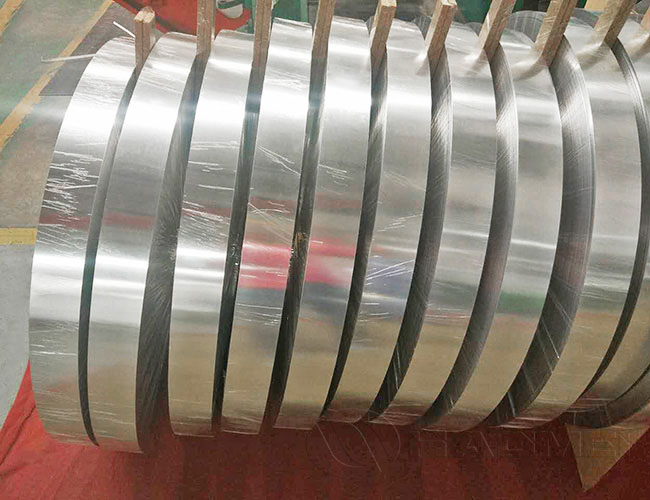

1060 Aluminum Strip for Sale

What is 1060 aluminum strip

1060 aluminum strip belongs to the 1000 series aluminum alloys. Its density is 2.68 g/cm3. The aluminum content is about 99.6% and other main components are carbon, chromium, iron, manganese, zinc and tin, etc.

1060 aluminum has the characteristics of high plasticity, corrosion resistance, good electrical conductivity and thermal conductivity, but low strength, not strengthened by heat treatment, poor machinability, and can accept contact welding and gas welding. It is widely used in air discharge pipes, hot water pipes, cold water pipes, heat exchangers, automobile manufacturing, machining and other industrial fields.

1060 aluminum chemical composition

Alloy | Fe | Si | Mn | Cu | Ti | V | Zn | Mg | Al | Others (each) |

1060 | 0.35 | 0.25 | 0.03 | 0.05 | 0.03 | 0.05 | 0.05 | 0.03 | 99.6 | 0.03 |

Different standards

China | Japan | United States | International Standards | Europe | ||

GB | JIS | ASTM | UNS | ISO | Number grade | EN |

1060 | 1060 A91060 | 1060 | A91060 | AI99.6 | A91060 | EN-AW-AI99.6 |

Specifications

Alloy | 1060 Aluminum Strip |

Tempers | F,O,H12,H14,H16,H18,H19,H22,H24,H26,H28,H111,H112,H114 |

Thickness | 0.15-4.0 mm |

Surface treatment | Plain aluminum, mirror finish, aluminum strip with film |

Packing method | simple package, fine package, fumigation-free wooden pallet |

Application | Aluminum strips for lighting materials, aluminum strips for dry-type transformers, aluminum strips for equipment, etc. |

Hardness

Temper | Hardness value(Webster hardness) |

1060 -H18 | 26-30 |

1060-H24 | 22-26 |

1060-O | 10-16 |

1060-H22 | 12-16 |

Properties of different tempers

1060-H18: It belongs to the non-annealing aluminum strip, also a kind of full hard aluminum strip, which is suitable for anodizing.

1060-H24: Its annealing process is relatively satisfactory in the overall data, so it can be bent at 90 degrees without cracking in terms of performance. It is suitable for stamping, shallow punching, and industrial applications.

1060-H14: It will do cold rolling after annealing. The advantage is that the flatness of the aluminum sheet is relatively good.

1060-O: It belongs to the fully annealed aluminum strip. It is a kind of soft aluminum strip, which is suitable for stamping and deep drawing.

1060-H112: It belongs to the annealing process of hot-rolled aluminum strip. Its performance will be better. There will be no problem of coarse grain size.

1060-H22: The softness is between the two of O and H24 temper. It is suitable for the applications which requires stamping and a certain strength.

Applications

Aluminum Transformer: 1060 aluminum strips have high conductivity and can replace copper strips as transformer aluminum strips.

Cable armoring: 1060 aluminum tape is used as cable armor protective layer.

Radiator: 1060 aluminum strip has good heat conduction effect, suitable for various radiators and heat exchangers.

Metal stamping: 1060 aluminum strip has stable ductility and high elongation rate, and is suitable for various stamping and drawing parts, such as utensils, lamps and other products that require stamping and drawing.

Differences from other alloys

1060 VS1050:They are very similar. The former has an aluminum content of 99.60%, and the latter has an aluminum content of 99.70%. Both alloy products are covered by the same ISO standard but with a different ASTM standard.

1060 VS 1100: The aluminum content of 1100 aluminium is more than 99.00% while that of 1060 aluminum is 99.6%. The tensile strength of 1100 aluminum strip is higher than that of 1060 aluminum, and the compressive strength is also higher. In addition, the 1100 aluminum strip has stronger corrosion resistance, brighter surface gloss and longer service life. Its price is much higher than that of 1060 aluminum.

1060 Vs 6061: 1060 alloy has moderate hardness and low price, and is commonly used in industry. 6061 aluminum has certain components of silicon and magnesium alloys, which have certain wear-resistant and anti-rust properties.

Their hardness varies a lot. 1060 has moderate hardness and can adapt to common processing conditions, such as bending, while 6061 has better hardness and is widely used in places with high hardness requirements.

1060 VS5052: The aluminum content of 1060 aluminum strip is 99.6%, and other elements are 0.4%, which is widely used in industries that do not require high strength. 5052 aluminum is an aluminum-magnesium alloy formed by adding a certain amount of magnesium to pure aluminum. The aluminum content is about 96%, the magnesium content is 2.2%-2.8%, and the rest are other elements, such as silicon, copper, iron, etc. 5052 aluminum is a famous marine grade aluminum alloy.

Original source: https://www.aluminumstrip24.com/products/1060-aluminum-strip.html

Tags: aluminium strip for transformer winding,

Previous: 1100 Pure Aluminum Strip

Next: 1050 Aluminium Metal Strip