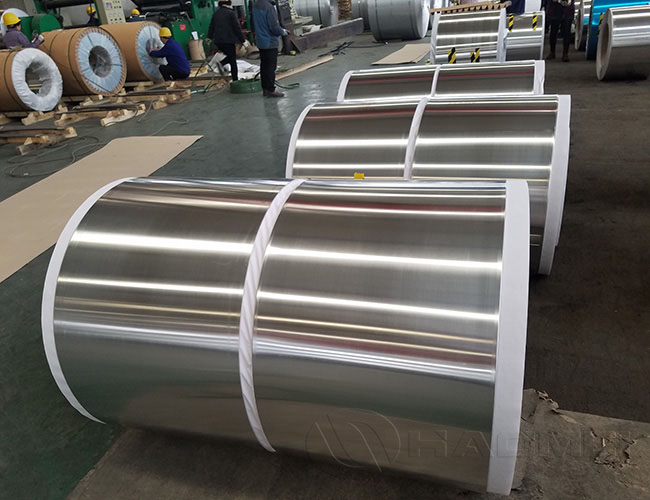

Different Thickness 3003 Aluminum Strip

What is 3003 aluminum strip

3003 aluminum strip belongs to Al-Mg alloy. Due to the manganese alloy element, it has excellent anti-rust properties, and is also called anti-rust aluminum strip. It cannot be strengthened by heat treatment, so cold working method is used to improve its mechanical properties. It has high plasticity in the annealed state, good plasticity in semi-cold work hardening, low plasticity in cold work hardening.

Its strength is about 10% higher than 1100, so 3003 aluminum is often used for processing parts that require good formability, high corrosion resistance,good weldability and higher strength than 1xxx aluminum alloys such as kitchen utensils, food and chemical product processing and storage, tanks, various pressure vessels and pipes, heat sinks, cosmetic panels, photocopier drums, ship materials,etc.

3003 aluminum chemical composition(%)

Alloy | Al | Si | Cu | Mg | Zn | Mn | Ti | Fe |

3003 | 99.8 | 0.6 | 0.05-0.2 | 0.02- | 0.10 | 1.0-1.5 | - | 0.7 |

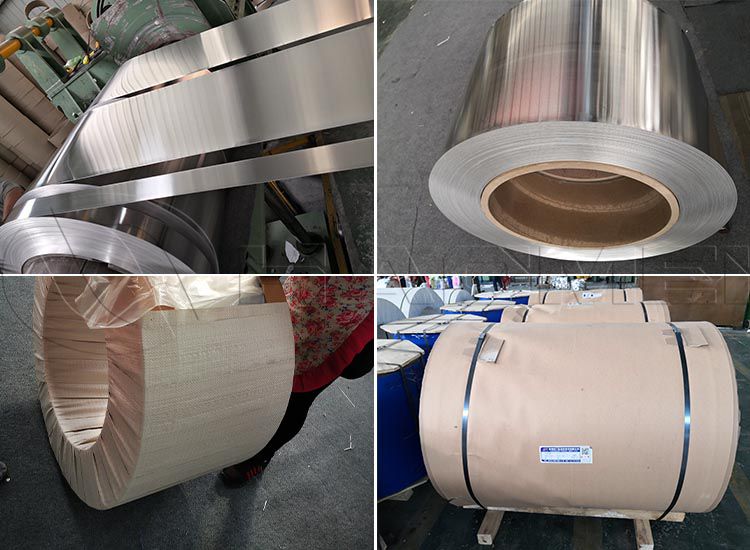

Specification

Alloy | Temper | Thickness(mm) | Width(mm) | Length(mm) | Application |

3003 | O,H12,H14,H16 H18,H19,H22,H24 H26,H28,H32,H34 H36,H38 | 0.2-8 | 100-2650 | C | Battery shell material, battery cover plate, automobile water cooling plate, wine bottle cap, beverage bottle cap, capacitor shell, etc. |

Mechanical properties

Tensile strength: 142-178 Mpa

Conditional yield strength:≥115 Mpa

Homogenization annealing temperature is 590~620 ℃

Hot rolling temperature is 480~520 ℃

Typical annealing temperature is 413℃, air cooling.

Chemical properties

The corrosion resistance of 3003 aluminum alloy is very good, close to the corrosion resistance of industrial pure aluminum, and has good resistance to atmosphere, fresh water, sea water, food, organic acid, gasoline, neutral inorganic salt solution, etc. Its corrosion resistance in dilute acid is also very good.

In the state of cold deformation, 3003 aluminum alloy has a tendency of exfoliation corrosion, and the greater the deformation, the more serious the exfoliation. Due to the uneven color after anodizing, it is generally not anodized.

Corresponding grades and standards

Japanese standard: A3003 JIS H4000-1999 JIS H4100-1999

African standard: 31000 IS 736-2001

Russian standard: AMu/1400 FOCT4785-1974

EN:EN AW-3003/AlMn1Cu EN 573-3-1994

German standard: AlMnCu/3.0517 DIM1725-1-1986

French standard: 3003 (A-M1) NFA50-411 NFA50-451

British Standard: 3103 (N3) BS 1470-1988

American Standard: 3003/A93003 AA/UNS

Common tempers of 3003 aluminum alloy

Because it can only be work hardened, 3003 aluminum alloy is commonly supplied in the H state, such as H12, H22, H14, H24, H26, H112, etc.

3003 H24 production process: casting rolling-annealing furnace annealing-finished product packaging. It belongs to the more commonly used one-time annealing product.

3003 H14 production process: Casting and rolling-annealing in annealing furnace-cold rolling-finished product packaging. 3003 h14 aluminum strip is rolled again after annealing, which has better plate shape.

3003h16 aluminum strip not only has good formability, but also has moderate strength. As a high-grade decorative material, it has high added value and has a broad market prospect.

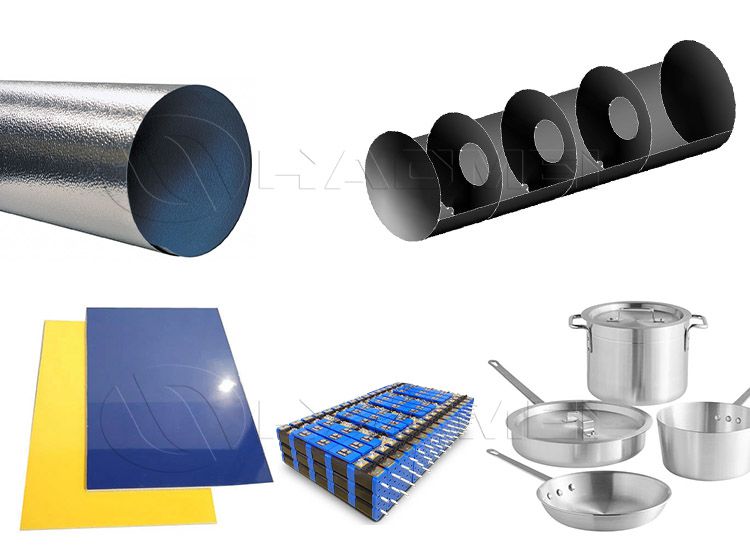

Applications of 3003 aluminum strips for sale

1. The power battery casing made of 3003 aluminum alloy has impact resistance, is not easy to break and leak, and can meet the strength and rigidity requirements of the power battery casing. The low density and light weight of aluminum alloy can reduce the weight of the battery, increase the capacity density of the battery, make the battery work stably, indirectly reduce the weight of the whole vehicle, and increase the endurance of the vehicle.

2. 3003 aluminum is also often used as the raw material of color coated aluminum sheet. 3003 color coated aluminum sheet and strip is widely used in construction (aluminum-plastic panels, aluminum honeycomb, roof corrugated panels, fireproof panels, aluminum ceilings, shutters, rolling doors, garage doors, awnings, gutters), electronic appliances (computer cases, electrical panels), lighting, furniture , solar reflectors, air conditioning ducts, etc.

3. It is also used in the fields of pipes, building roof and wall insulation materials, etc. Generally, 3003 aluminum coils with a thickness of 0.4-1.0mm are used for thermal insulation. 3003 thermal insulation aluminum coil is characterized by anti-rust and anti-corrosion properties.

4. 3003 aluminum is a high-end pot raw material. Especially in the field of kitchen utensils, storage or some liquids, 3003 aluminum plate is used as the base material of the bottom plate. Another important bottle cap material is 3105 aluminum strip.

5. The price of 3003 is cheaper than that of 5052, and its welding performance is also very good. Some truck fuel tank material manufacturers also use 3003H24 aluminum plate to replace 5052 to make bulkhead in the fuel tank that do not need to bear pressure, which reduces the cost without affecting the use.

6. Based on the characteristics of easy processing and good rust resistance, 3003 aluminum alloy is also used in the manufacture of pressure vessels, refrigeration devices, TV towers, drilling equipment, transportation equipment, missile components, armor and other products that require strict fire protection.

Original source: https://www.aluminumstrip24.com/products/3003-aluminum-strip.html

Tags: aluminium strip ceiling,

Previous: 1145 Aluminum Foil Strip

Next: 3105 Aluminum Strips for Sale