Black Anodised Aluminum Strip and Brushed Aluminum Trim Strip

Aluminum naturally has excellent anti-corrosion properties, which are only enhanced during the anodizing process. Anodizing is an electrochemical process that changes the surface of a metal to give it a durable, corrosion-resistant surface. This protective layer is formed from anodized oxide, which is actually part of the metal itself rather than just a surface coating, meaning it's more durable and attractive.

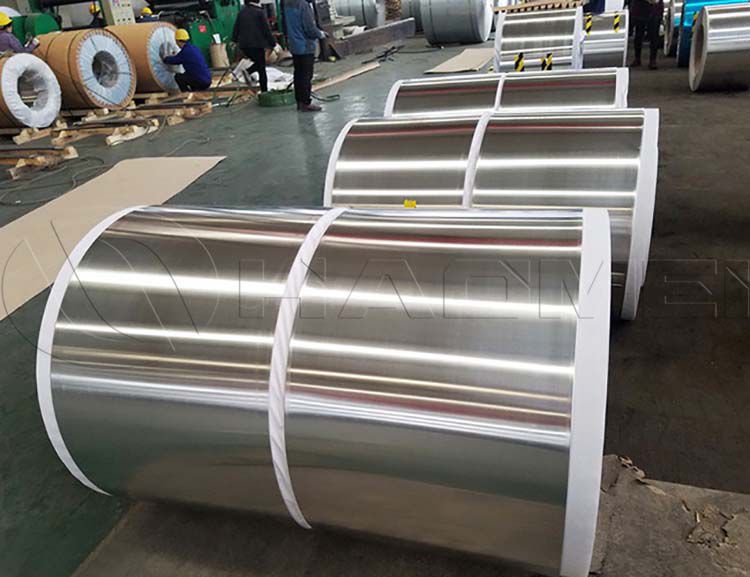

Because its surface is treated with an anodizing process, its colors are rich and diverse. A popular one is the black anodised aluminum strip. Its price is much lower than copper and stainless steel. The anodized aluminum strip is famous for being light and thin, waterproof and fireproof, and not easily deformed.

The brushed aluminum trim strips use mechanical methods to carve continuous or discontinuous scratches on the surface of the flexible aluminum strips, and then undergoes anodizing treatment to form an Al2O3 film layer on the surface of the aluminum strip, which is then coated, colored, and printed to form the final product.

It is lightweight, wear-resistant, corrosion-resistant, and has excellent impact resistance. And it is a green, environmentally friendly, fire-proof and weather-resistant high-end decorative material. All these properties make it widely used in home appliances, electronic communications, transportation, building materials and decoration and other fields.

Brushing and anodizing are two different surface treatment processes for aluminum plates. Brushed aluminum strip is a manufacturing process in which the aluminum plate is forced through the mold under the action of external force and the lines are drawn out. The main process of the process is divided into three parts: deesterification, sand mill and water washing.

Anodized aluminum strip is an aluminum plate placed in the corresponding electrolyte as an anode. Under specific conditions and the action of external current, electrolysis is performed. The main process includes degreasing, etching, neutralization, anodizing, coloring, and sealing.

In terms of performance, brushed aluminum trim strip is the same as ordinary aluminum strip, which is easy to scratch, not resistant to UV rays, and not resistant to washing. However, the surface of the anodized brushed aluminum strip will form a very good protective film, which can protect the brushed aluminum strip very well.

This special oxide film cannot be oxidized directly by placing the aluminum plate in the air. The brushed aluminum strips that are naturally oxidized in the air cannot provide anti-corrosion effects.

Original source: https://www.aluminumstrip24.com/news/black-anodised-aluminum-strip-and-brushed-aluminum-trim-strip.html

Tags: flexible aluminum strips,

Previous: What Is Aluminum Strip Width

Next: Is The Aluminium Strip Easy to Scratch