Two Popular Uses of Aluminum Strips

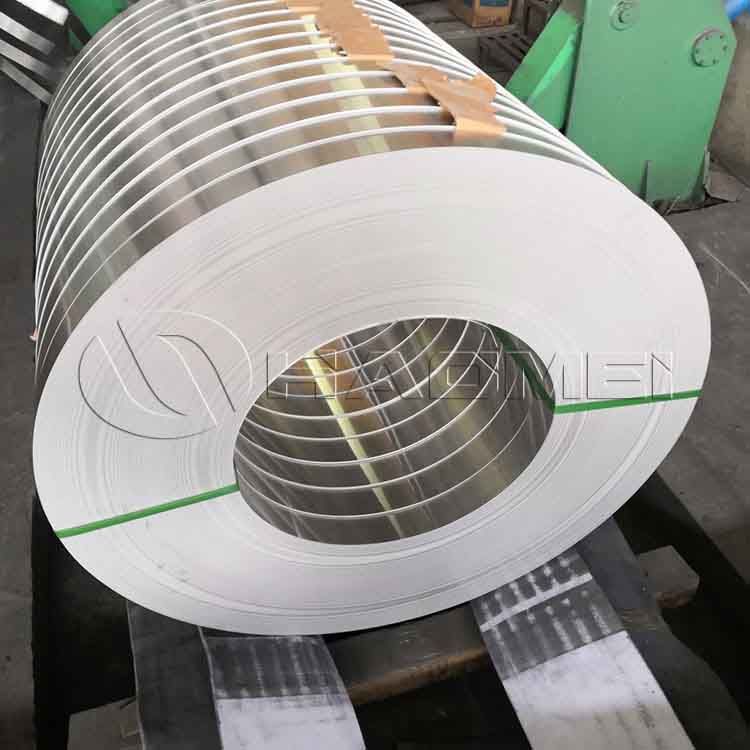

In the vast family of industrial materials, aluminum strip may seem to play a supporting role, yet it plays an irreplaceable part in countless critical scenarios. Aluminum strips for sale, made from pure aluminum or aluminum alloy through rolling and slitting, permeate every aspect of our lives thanks to its core advantages of lightweight, corrosion resistance, and ease of processing.

Pharmaceutical Bottle Caps

The safety of pharmaceutical packaging is directly related to the health of those taking medication, and aluminum strip is the core material for manufacturing pharmaceutical bottle caps. Compared to other materials, aluminum strip's hygienic inertness, ease of forming, and reliable sealing perfectly meet the stringent requirements of the pharmaceutical industry, making it a trusted choice for pharmaceutical packaging.

Aluminum strip for pharmaceutical caps adheres to extremely precise quality standards. From a chemical composition perspective, its alloy ratio must strictly follow national standards, precisely controlling the content of elements such as magnesium and iron to ensure both material strength and processing performance. The thickness is typically controlled between 0.15mm and 0.3mm.

This thin and lightweight characteristic facilitates stamping and ensures ease of opening the cap. During the production process, aluminum strip undergoes processes such as oiling, precise feeding, and multiple stamping steps to ultimately create bottle caps that are clean inside and out, free of burrs, avoiding the risk of aluminum shavings contaminating medicines due to material issues.

Beyond basic physical properties, the corrosion resistance and hygiene safety of aluminum strip are crucial. Verified through both neutral salt spray and acetic acid immersion tests, bottle caps made from aluminum strip effectively resist corrosion from humid environments and acidic contents, while ensuring that heavy metal migration meets food safety standards.

For medicines requiring light-proof storage, the light-blocking properties of aluminum strip can also help extend the shelf life of medicines, providing comprehensive protection for drug quality. Today, from antibiotic bottles to oral liquid bottles, aluminum bottle caps have become the mainstream choice for pharmaceutical packaging, thanks to the stable support of aluminum strip materials.

Roller Shutters

Roller shutters are widely used in commercial shops, industrial plants, and other settings, and aluminum strip is a core component that enhances their performance. Its unique material advantages allow roller shutters to achieve multiple breakthroughs in safety, durability, and practicality, becoming a "reliable barrier" protecting doors.

Structural support is the primary function of aluminum strips in roller shutter doors. The roller shutter slats, formed from processed aluminum strips, possess both strength and toughness, effectively resisting external impacts and providing basic safety for the environment.

Compared to traditional steel, the aluminum strip for roller shutter offers significant weight reduction advantages, not only lowering the overall weight of the roller shutter door, reducing motor load and mechanical wear, but also improving the smoothness of door operation and reducing long-term maintenance costs.

Corrosion resistance makes aluminum roller shutter doors suitable for a wider range of applications. Aluminum strips naturally form a dense protective oxide film in the air, making them resistant to rust even in humid, dusty outdoor environments, significantly extending the lifespan of the roller shutter door.

Furthermore, aluminum strips are highly malleable, allowing them to be processed into profiles of various specifications according to design requirements. They can also undergo diverse surface treatments through processes such as coating and anodizing, satisfying both the aesthetic needs of shopping malls and the practical requirements of industrial plants.

It is worth mentioning that aluminum strips also endow roller shutter doors with additional practical functions. By employing a double-layered hollow aluminum strip slat structure, the thermal insulation performance of the door is effectively improved, helping to regulate indoor temperature and reduce energy consumption.

In terms of ease of operation, the lightweight aluminum strip slats make raising and lowering the roller shutter door easier, whether manually or by motor, resulting in smoother operation and perfectly adapting to the different usage needs of commercial and industrial scenarios.

Original source: https://www.aluminumstrip24.com/news/two-popular-uses-of-aluminum-strips.html

Tags: aluminum strips for sale,

Previous: 1060 1070 Aluminum Foil Strip Coil

Next: What Are Uses of Color Coated Aluminum Strips