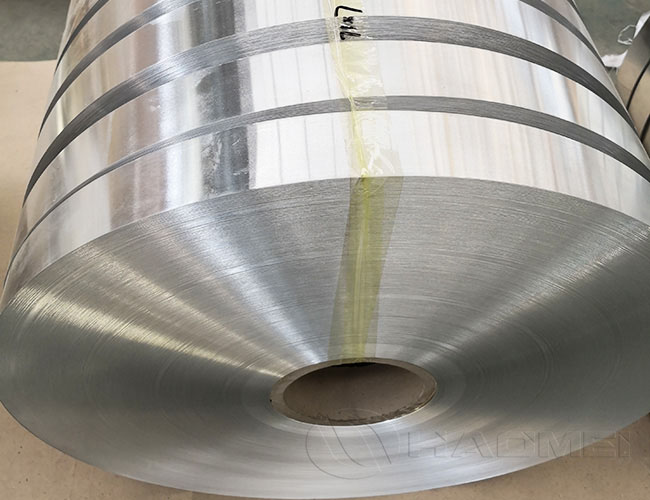

1050 Aluminium Metal Strip

What is 1050 Aluminum Metal Strip

1050 aluminum strip contains more than 99.5% aluminum, which is a kind of industrial pure aluminum. 1050 aluminum alloy is formed by adding a small amount of copper to pure aluminum. It has excellent forming and processing characteristics, high corrosion resistance, good weldability and electrical conductivity, but its strength is low.

Its chemical composition and mechanical properties are similar to those of 1060 aluminum alloy, and are basically replaced by 1060 aluminum strips in application. It can be used for gas welding, argon arc welding and spot welding.

Features of 1050 aluminum

It has strong reflectivity, good brightness and smoothness. After anodizing and coloring, it can not only further improve the corrosion resistance, but also obtain colorful and dazzling products. It is very suitable as a high-end decorative material. At the same time, because of its good photosensitivity, it is also one of the main alloys for making PS and CTP plate.

Chemical composition

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Zr | Al | Others(each) |

1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | - | 0.05 | 0.03 | - | 99.5 | 0.03 |

Mechanical properties

Alloy | Physical Properties | Value |

1050 H14 | 2.71 g/cm3 | |

650℃ | ||

Thermal Expansion | 24 x10^-6 /K | |

Modulus of Elasticity | 71 GPa | |

Thermal Conductivity | 222 W/m.K | |

Electrical Resistivity | 0.0282 x10^-6 Ω .m |

Alloy | Physical Properties | Value |

1050 H24 | Density | 2.71 g/cm3 |

Melting Point | 646-657 ℃ | |

Tensile Strength Rm/Mpa | 105-145 | |

Yield Strength Rp0.2/Mpa | 75 | |

Yield % | 3 | |

Hardness HBWα | 33 |

Specification

Alloy | 1050 |

Tempers | H14, H24,H16 |

Thickness | 0.2-8 mm |

Width | 100-2650 mm |

Length | custom |

Applications | CTP/PS aluminum base plate, aluminum-plastic plate, lamp material, battery explosion-proof valve, tab,etc. |

Main tempers

1050-H14: It is work hardened by rolling to half hard, not annealed after rolling. Its production process includes: casting, sawing, milling, heating, hot rolling, and cold rolling. The 1050-H14 aluminum strip not only has good processing formability, but also has moderate strength. It is produced as a high-grade decorative material.

1050-H16: It is strain hardened to a strength that is roughly 3/4 of the way between announced (O) and full-hard (H18). So H16 is harder than H14, mainly because of its high tensile strength.

1050-H24: It is strain hardened, and then partially annealed, to a strength that is roughly halfway between annealed (O) and full-hard (H28).

Applications

PS/CTP plate: It usually chooses 1000 series aluminum alloy like 1050, 1060 and 1100 aluminum sheet. It has the advantages of low density, high strength, good formability, good hydrophilicity, high stability, and good surface treatment, and has become an indisputable PS/CTP plate substrate. After electrolytic grinding and anodic oxidation, a layer of photosensitive material is coated on the surface of the aluminum alloy plate including PS plate, UVCTP plate and CTP plate.

Aluminum bottle caps: They are currently popular new packaging materials in domestic and foreign markets. Compared with traditional plastic or tinplate bottle caps, aluminum bottle caps have better sealing performance, high pressure resistance, corrosion resistance, beautiful appearance and environmental protection. At present, the aluminum cosmetic bottle caps are mainly made of 1070, 1050, 5005 and other aluminum alloys.

Lithium battery explosion-proof valve: It is made of aluminum alloy material, and the surface is hard and anti-corrosion. This product not only has the function of a traditional dustproof, waterproof and breathable valve, but also has explosion-proof and alarm functions. Compared with ordinary plastic explosion-proof valves, it has the advantages of high temperature resistance, strong impact resistance, strong corrosion resistance, long service life, high explosion-proof precision, easy installation, strong waterproof, high air permeability, and reusable ability.

Tabs: They are a raw material for lithium-ion polymer battery products. They are metal conductors that lead out the positive and negative electrodes from the battery. The tab material is made of pure aluminum foil with a purity greater than 99.9%, which has high conductivity. The positive tab of the lithium-ion battery is made of 1050 aluminum foil. Its conductivity is 369000 S/cm.

Original source: https://www.aluminumstrip24.com/products/1050-aluminum-strip.html

Tags: aluminium strip for transformer winding,

Previous: 1060 Aluminum Strip for Sale

Next: 1145 Aluminum Foil Strip